Product

-

EV High-Voltage Cable

-

EV Charging cable

ISO19642 HV Cable

EV High-Voltage Cable introduction:

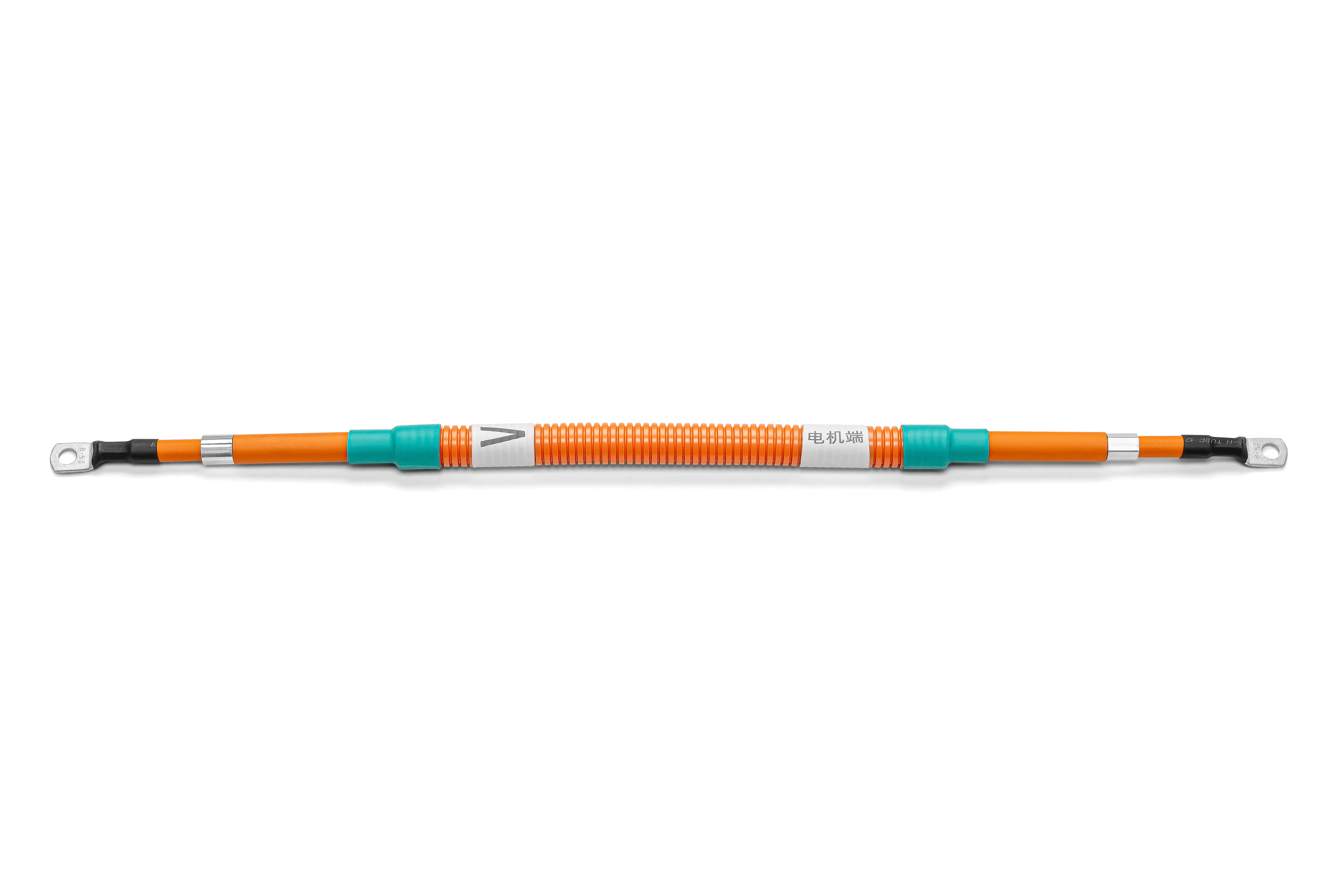

On electric vehicles, the high-voltage electrical system is mainly responsible for starting, driving, charging and discharging, and air conditioning power. It mainly includes battery system, powertrain, high-voltage electronic control system, charging system, high-voltage equipment, and its wiring harness system. Electric vehicle high-voltage lines are used to connect the charging port and the battery, the interior of the battery, the battery and the engine and other components, as well as battery energy storage equipment and other fields, as the carrier of power transmission. Due to the harsh application environment in the vehicle, electric vehicle high-voltage cables have very high performance requirements. Application characteristics of cables for electric vehicles: small wiring space, high current and high voltage, high and low temperature environment, poor heat dissipation, bad driving environment with salt spray and electromagnetic field, oil pollution and chemicals, low smoke halogen-free flame retardant,

Test OMG EV high voltage cable (Part 1)

Test OMG EV high voltage cable (Part 2)

Common choices for EV high voltage cables:

| Usage Environment | Common specifications mm2 | Material | Features |

| Drive motor--MCU | 35mm2、50mm2、70mm2*3 | 180°C silicone or 150°C XLPE | Thermosetting material, high temperature resistance, soft, shielding structure Structure, tear resistance |

| Air Conditioning System - PDU | 2.5mm2、4mm2、6mm2*2 | 125°C XLPE | Soft, shielded construction |

| Small Battery-DC/DC | 10mm2、16mm2、25mm2 | 125°C XLPE | Soft |

| DC/DC--PDU | 16mm2、25mm2*2 | 125°C XLPE | Soft, shielded construction |

| MCU--PDU | 35mm2、50mm2、70mm2*2 | 125°C XLPE | Soft, shielded construction, tear-resistant |

| Car charger-battery | 6mm2、10mm2 | 125°C XLPE | Soft, shielded construction |

| Battery - PDU | 50mm2、70mm2*2 | 125°C XLPE | shielded construction |

| Battery - BMS | 20AWG | 200℃ FEP | High temperature resistant, smooth |

| Battery - DC Charging Stand | 35mm2、50mm2、70mm2*2 | 125°C XLPE | High temperature resistance, anti-cracking |

Related Product Links:

Liquid-cooled high voltage Cable

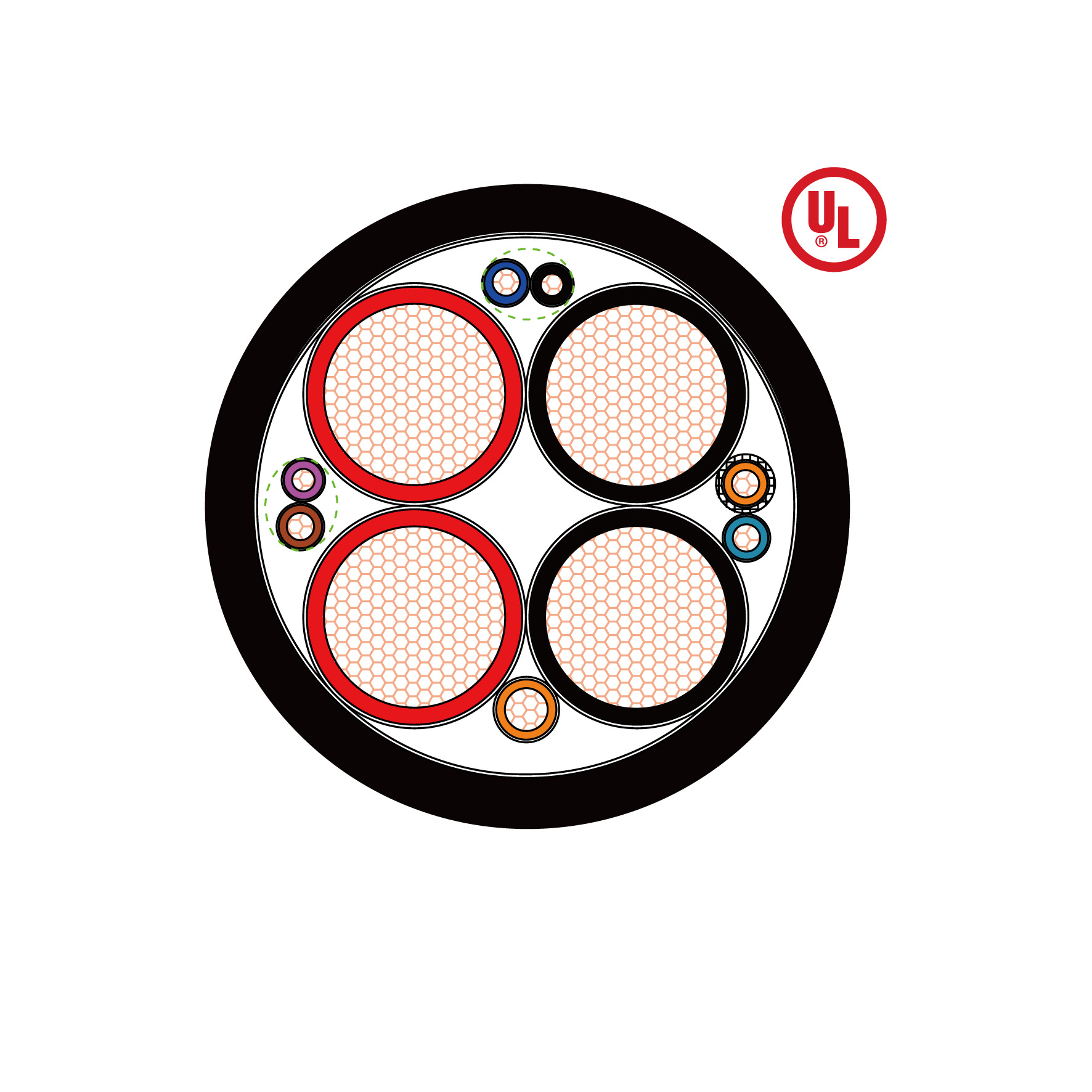

UL certified EV high voltage cables

IS0 19642 standard EV high voltage cable

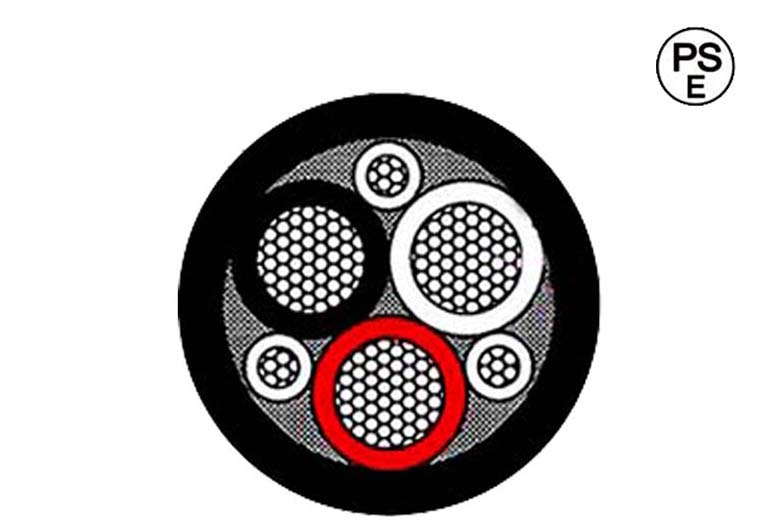

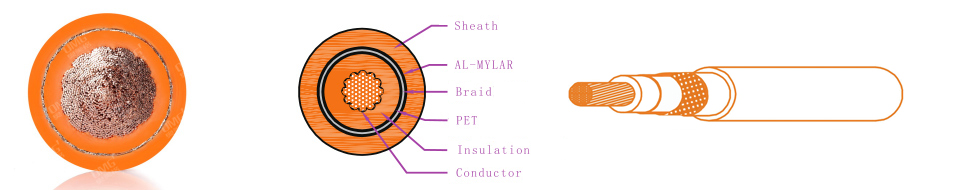

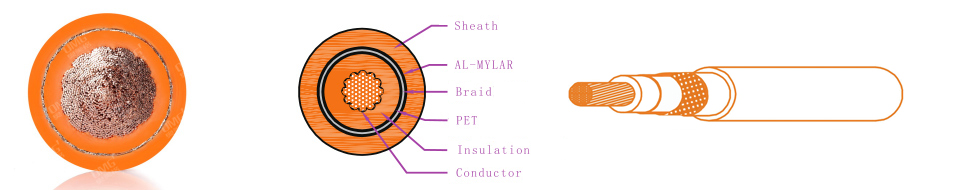

Product description for high voltage cables for road vehicles:

(Reference Standard: IS0 19642-2019-5、IS0 19642-2019-9)

E-MARK Approval No: E24*118R03/01*0375*00

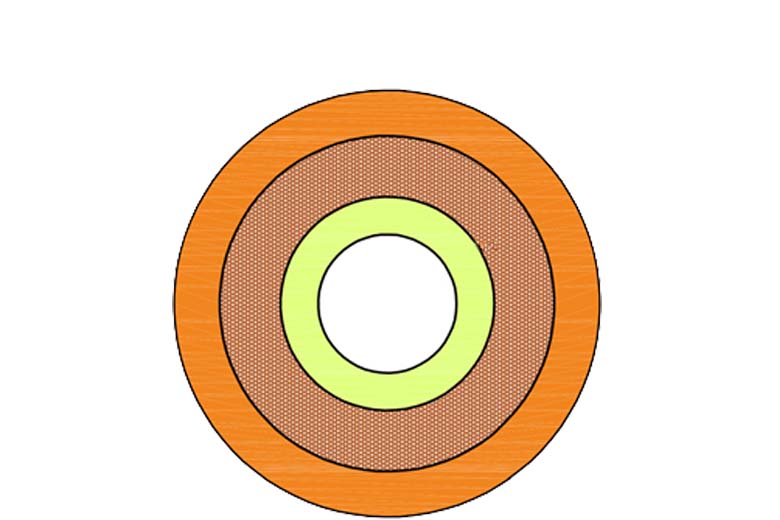

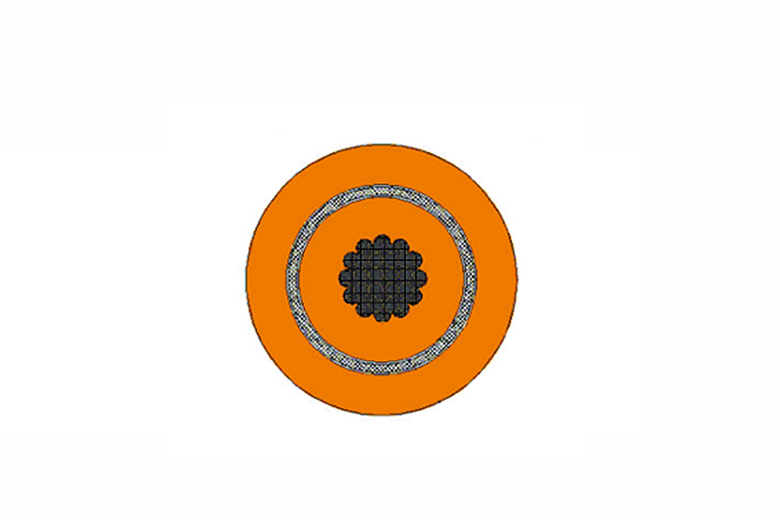

| Construction | Features |

| 1、Conductor1 | 1、Rated temperature :-40℃~+(125℃, 150℃) |

| Material: Bare Copper | 2、Rated Voltage:AC 600V/DC 900V;AC 1000V/DC 1500V |

| 2、Insulation | 3、Short-term Aging:240h,Comply with IS0 19642 |

| Material: XLPE | 4、Long-term Aging: 3000h,Comply with IS0 19642 |

| Color:Orange | 5、Flame Test: Comply With IS0 19642 |

| 3、Shielded | 6、Bending Radius: 4*OD@OD﹤15mm ; 6*OD@OD≧15mm |

| Material:Tinned Copper | 7、Dielectric Voltage:10kVac/5min. No Breakdown |

| 4、Sheath | 8、Oil Resistance:Comply With IS0 19642 |

| Material: XLPE | 9、Anti-tear Performance :>20N/mm |

| Color:Orange | 10、Environmental Requirements:Compliant with RoHS 2.0 and REACH |

1.AC 1000V/DC 1500V (shielded High-voltage cable):

AC 1000V/DC 1500V (shielded High-voltage cable):

| Product Series | Size | Conductor Stranded OD mm ( Ref.) | Max. Conductor resistance mΩ/m@20℃ | Permissible ampacity A (Ref.) | Over diameter mm (Ref.) | |

EVRP-125 (Rated temperature :-40℃~+125℃)

(Rated temperature :-40℃~+150℃) |

2.5mm2 | 2.00 | 7.60 | 30 | 6.30 | |

| 4mm2 | 2.60 | 4.71 | 40 | 7.30 | ||

| 6mm2 | 3.40 | 3.14 | 52 | 8.10 | ||

| 10mm2 | 4.40 | 1.82 | 75 | 9.80 | ||

| 16mm2 | 5.50 | 1.16 | 100 | 11.00 | ||

| 25mm2 | 7.00 | 0.743 | 125 | 13.40 | ||

| 35mm2 | 8.30 | 0.527 | 165 | 14.80 | ||

| 50mm2 | 10.00 | 0.368 | 215 | 17.00 | ||

| 70mm2 | 11.80 | 0.259 | 260 | 19.00 | ||

| 95mm2 | 13.80 | 0.196 | 320 | 21.60 | ||

| 120mm2 | 15.50 | 0.153 | 400 | 23.30 | ||

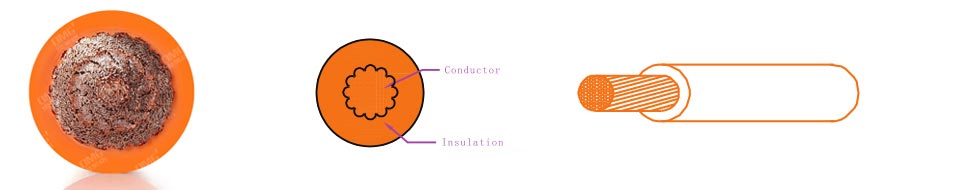

2. AC1000V/DC 1500V (unshielded High-voltage cable):

AC1000V/DC 1500V (unshielded High-voltage cable):

| Product Series | Size | Conductor Stranded OD mm ( Ref.) | Max. Conductor resistance mΩ/m@20℃ | Permissible ampacity A (Ref.) | Over diameter mm (Ref.) | |

EVR-125 (Rated temperature :-40℃~+125℃)

(Rated temperature :-40℃~+150℃) |

2.5mm2 | 2.00 | 7.60 | 30 | 3.50 | |

| 4mm2 | 2.60 | 4.71 | 40 | 4.30 | ||

| 6mm2 | 3.40 | 3.14 | 52 | 5.10 | ||

| 10mm2 | 4.40 | 1.82 | 75 | 6.50 | ||

| 16mm2 | 5.50 | 1.16 | 100 | 7.60 | ||

| 25mm2 | 7.00 | 0.743 | 125 | 9.70 | ||

| 35mm2 | 8.30 | 0.527 | 165 | 11.00 | ||

| 50mm2 | 10.00 | 0.368 | 215 | 13.10 | ||

| 70mm2 | 11.80 | 0.259 | 260 | 15.00 | ||

| 95mm2 | 13.80 | 0.196 | 320 | 17.10 | ||

| 120mm2 | 15.50 | 0.153 | 370 | 18.80 |

||

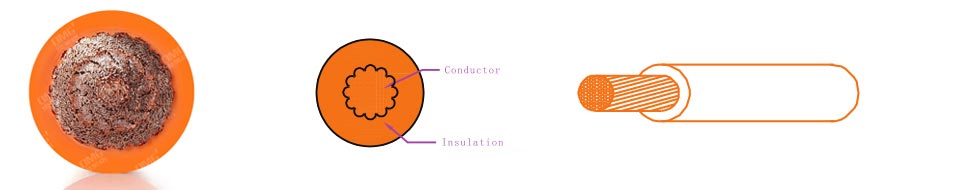

3、 AC 600V/DC 900V (unshielded High-voltage cable):

AC 600V/DC 900V (unshielded High-voltage cable):

| Product Series | Size | Conductor Stranded OD mm ( Ref.) | Max. Conductor resistance mΩ/m@20℃ | Permissible ampacity A (Ref.) | Over diameter mm (Ref.) | |

EVR-125 (Rated temperature :-40℃~+125℃)

(Rated temperature :-40℃~+150℃) |

2.5mm2 | 2.00 | 7.60 | 30 | 2.80 | |

| 4mm2 | 2.60 | 4.71 | 40 | 3.50 | ||

| 6mm2 | 3.40 | 3.14 | 52 | 4.30 | ||

| 10mm2 | 4.40 | 1.82 | 75 | 5.70 | ||

| 16mm2 | 5.50 | 1.16 | 100 | 6.90 | ||

| 25mm2 | 7.00 | 0.743 | 125 | 8.40 | ||

| 35mm2 | 8.30 | 0.527 | 165 | 10.00 | ||

| 50mm2 | 10.00 | 0.368 | 215 | 12.00 | ||

| 70mm2 | 11.80 | 0.259 | 260 | 14.00 | ||

| 95mm2 | 13.80 | 0.196 | 320 | 16.50 | ||

4、AC 600V/DC 900V (shielded High-voltage cable):

AC 600V/DC 900V (shielded High-voltage cable):

| Product Series | Size | Conductor Stranded OD mm ( Ref.) | Max. Conductor resistance mΩ/m@20℃ | Permissible ampacity A (Ref.) | Over diameter mm (Ref.) | |

EVRP-125 (Rated temperature :-40℃~+125℃)

(Rated temperature :-40℃~+150℃) |

2.5mm2 | 2.00 | 7.60 | 30 | 4.50 | |

| 4mm2 | 2.60 | 4.71 | 40 | 5.20 | ||

| 6mm2 | 3.40 | 3.14 | 52 | 6.40 | ||

| 10mm2 | 4.40 | 1.82 | 75 | 7.90 | ||

| 16mm2 | 5.50 | 1.16 | 100 | 9.40 | ||

| 25mm2 | 7.00 | 0.743 | 125 | 11.00 | ||

| 35mm2 | 8.30 | 0.527 | 165 | 12.90 | ||

| 50mm2 | 10.00 | 0.368 | 215 | 15.00 | ||

| 70mm2 | 11.80 | 0.259 | 260 | 17.00 | ||

| 95mm2 | 13.80 | 0.196 | 320 | 19.60 |

||

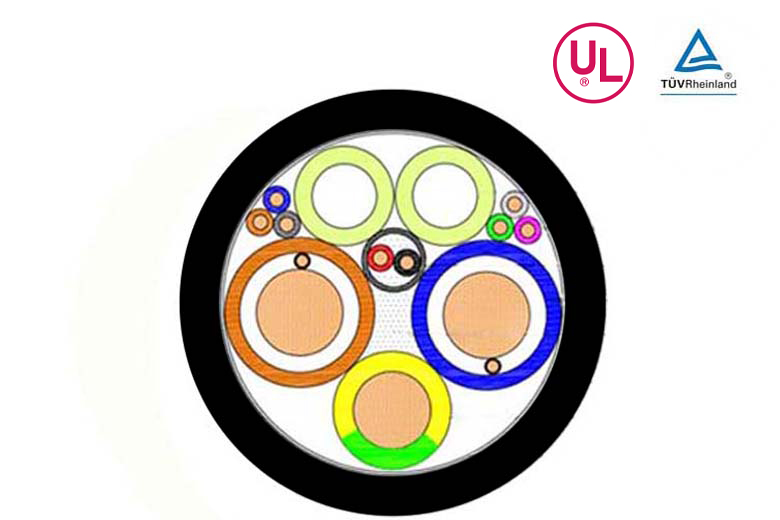

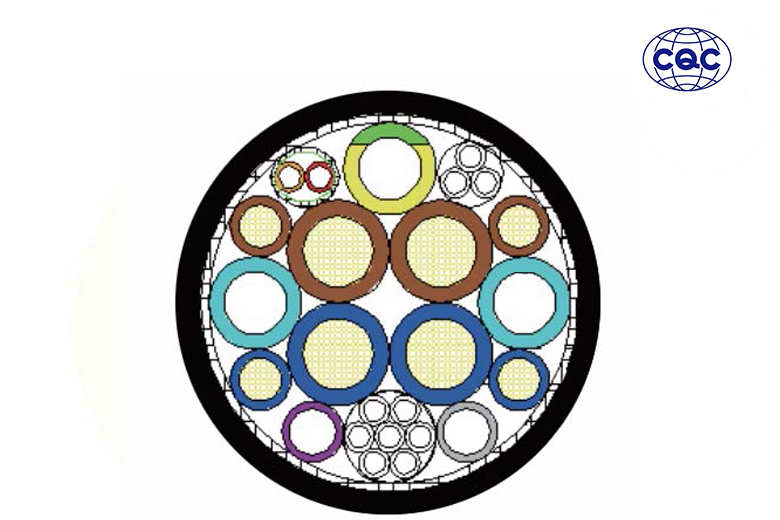

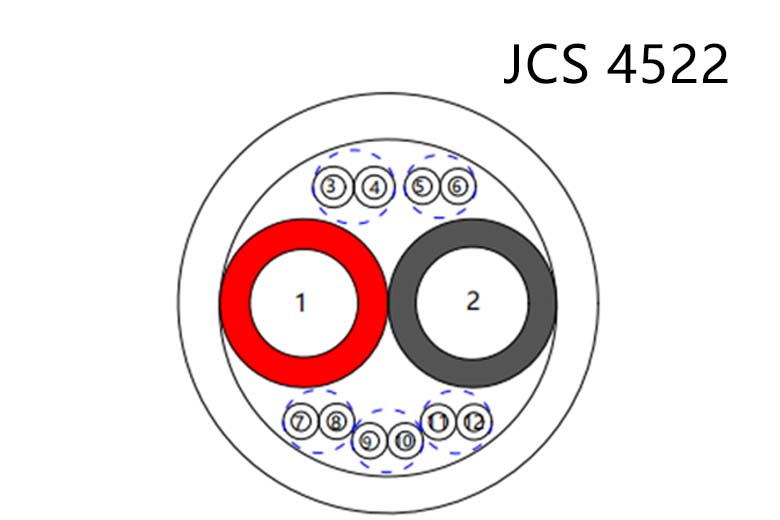

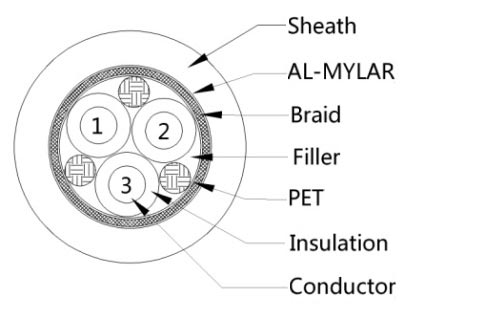

5、AC600V/DC 900V (multi-core shielded High-voltage cable):

AC600V/DC 900V (multi-core shielded High-voltage cable):

| Product Series | Cores | Size | Conductor Stranded OD mm ( Ref.) | Max. Conductor resistance mΩ/m@20℃ | Permissible ampacity A (Ref.) | Over diameter mm (Ref.) | |

QBJP2-C (Rated temperature :-40℃~+125℃)

(Rated temperature :-40℃~+150℃) |

2 | 1.5mm2 | 1.60 | 12.70 | 13 | 7.60 | |

| 3 | 11 | 8.00 | |||||

| 4 | 10 | 8.60 | |||||

| 5 | 9 | 9.20 | |||||

| 2 | 2.5 mm2 | 2.06 | 7.60 | 18 | 8.60 | ||

| 3 | 16 | 9.20 | |||||

| 4 | 14 | 9.90 | |||||

| 5 | 13 | 10.80 | |||||

| 2 | 4 mm2 | 2.70 | 4.71 | 26 | 10.10 | ||

| 3 | 22 | 10.60 | |||||

| 4 | 20 | 12.00 | |||||

| 5 | 18 | 13.20 | |||||

| 2 | 6 mm2 | 3.40 | 3.14 | 33 | 11.80 | ||

| 3 | 29 | 12.60 | |||||

| 4 | 26 | 13.60 | |||||

| 5 | 23 | 14.80 | |||||