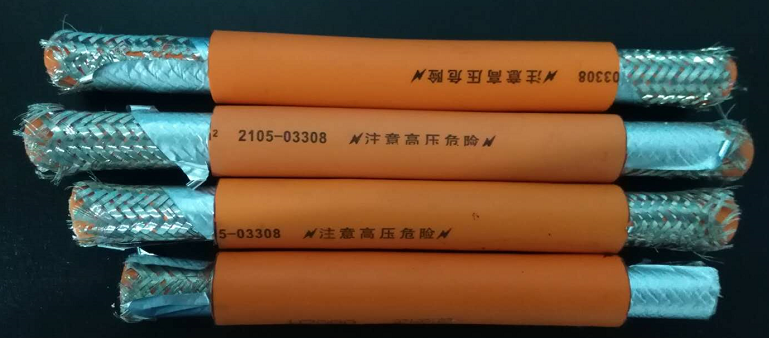

OMG EV cable single test report

Test the conventional ability of OMG EV cables

Tensile strength and elongation are the maximum acceptable tensile force of the test object. The above is the comparison between the test before (left) and after the test (right). The elongation is almost 1.5 times the original.

The tear resistance refers to the tear resistance at the tip in the case of cracks, which is 20N/mm² (approximately two kilograms per square millimeter) according to the operation of the tester.

Thermal deformation 150℃*1H

Thermal deformation is to place the cable in a 150°C environment for 1 hour and observe the depth of the indentation. The indentation is not broken, and the indentation rate is less than 50%.

Thermal shock means that due to the rapid heating or cooling, the object generates a large amount of heat exchange in a short period of time. When the temperature changes drastically, the object will produce shock thermal stress; after the test (below), the cable does not Variety.

Volume resistance is also called volume resistivity or volume-specific resistance

OMG EV Cabels can withstand the maximum voltage strength, 6KV / 15min

Hot extension: 200℃*15min

The elongation of the cable after heating (in the case of tension), the main consideration is the degree of crosslinking of polyethylene, the higher the degree of crosslinking, the smaller the thermal extension. The specific extension can be seen from the above figure.

Open flame burning cable, extinguish immediately

High-temperature pressure

Under the condition of 150℃*4 hours, the lifting weight is 600g, only one thin indentation is seen, and the cable is not broken, and the indentation ratio is less than 50%.

Heat shrinkage: 150℃* 15min

Thermal shrinkage is the volume change of the thermoplastic material due to its inherent thermal expansion rate. There is no significant change in the upper graph (before the test) and the lower graph (after the test).

Low-temperature winding: -40℃*4H

There is no fission on the outside, even if the temperature is very low, it is still easy to be good. Minimum temperature: The performance of a round cable or a round insulated core under low temperature is evaluated.

Long-term aging: 150℃*3000H

After 3000 hours under 150 months, the long-term aging is only the deformation of the outer cover, and there is no crack

Short-term aging 175℃*240H

Placed at 175℃ for 240 hours, short-term high temperature, no change in cable

Thermal overload: 200℃*6H

Under the environment of 200℃, the cable is overloaded for 6 hours, as can be seen from the following figure (after the test), the cable has not changed.

Through the above tests, OMG cables are always kept as they are to the greatest extent in various environments, and there is no huge change in the ability to use cables, so that the cables can withstand the use of various types of environments.