Product

-

EV High-Voltage Cable

-

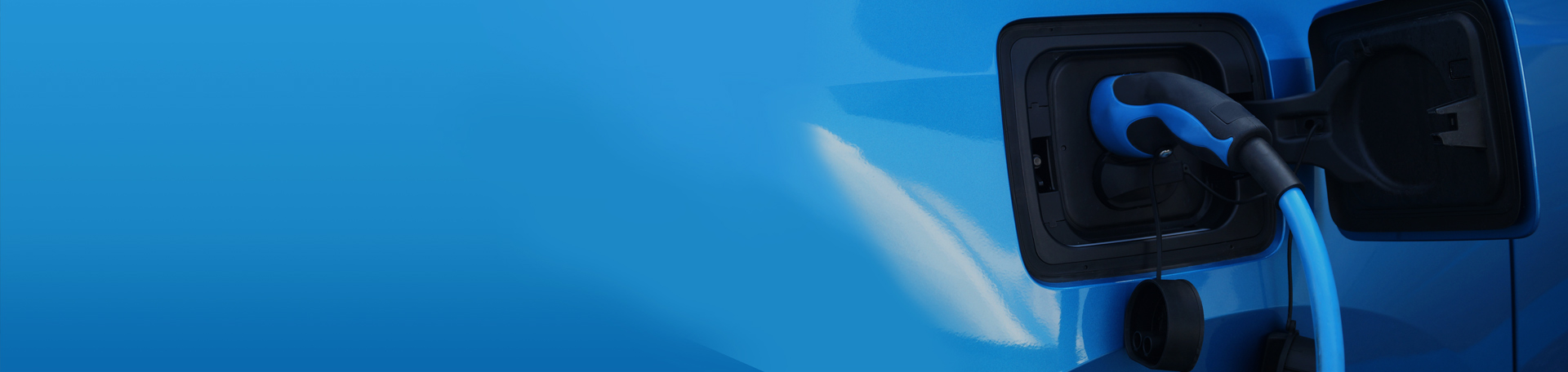

EV Charging cable

EV charging cable

EV charging cables are used to connect electric vehicle charging devices and charging infrastructure to transmit power to electric vehicles and are equipped with a certain amount of signal lines, control lines, power auxiliary lines, etc. to ensure accurate control of the entire charging process and safe operation. Charging cables are generally used in charging stations, parking lots, hotels, communities, garages, and other areas. Portable charging cables can be placed in the car.

OMG ev charging cable product standard:

The main standards for electric vehicle charging cables are: IEC62893, EN50620 (IEC62893-3 is equivalent to EN50620), UL2263, JCS4522, PSE, GB/T 33594, CQC1103-1105, DEKRA K175, TUV 2PFG 1908

| IEC standard | IEC 62893-1/2/3:2017 |

| European standard | EN 50620:2017(less than 35mm2) |

| Chinese standard | GB/T 33594-2017 |

| US/Canadian Standard | UL2263 |

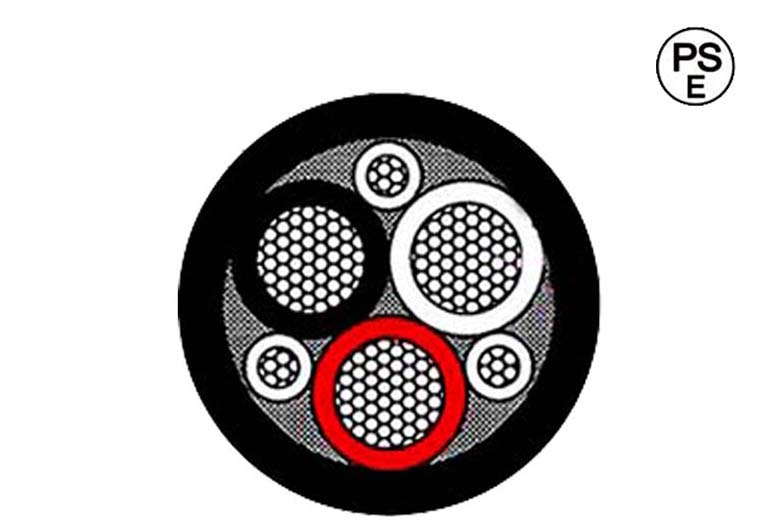

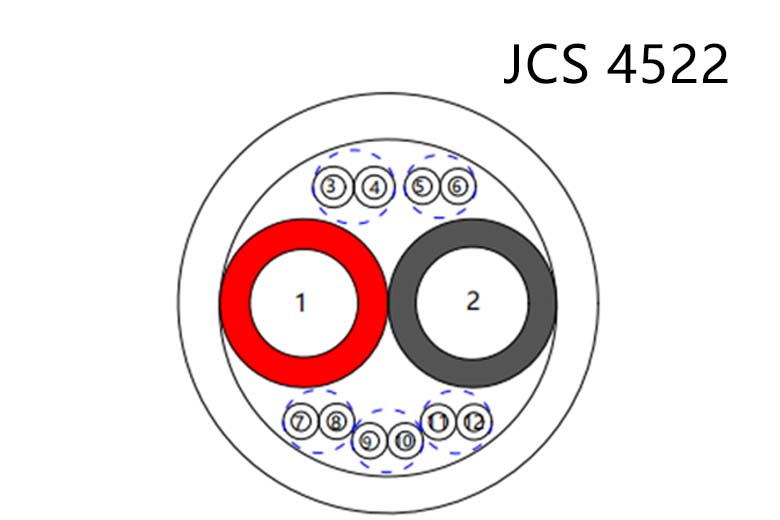

| Japanese standard | JCS 4522、PSE |

OMG ev charging cable product advantages:

The products are flexible with a bending radius less than 5D, surviving from high and low temperature, providing oil resistance, acid and alkali resistance, water resistance, abrasion resistance, crack resistance, UV resistance, good flame retardancy, good electrical conductivity, and insignificant conductor temperature rise. All materials comply with RoHS2.0 environmental protection standards.

Click on the link to see use cases for EV charging cables:https://www.omgevcable.com/Cases/

--------------

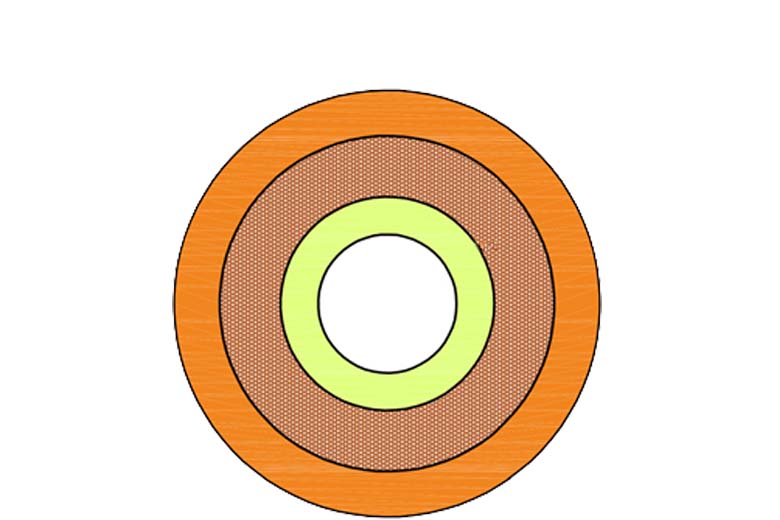

EN 50620, IEC62893 standard ev charging cable product introduction:

Reference Standard:EN 50620:2017、IEC62893-3:2017、DEKRA K175

Certificate No.:DEKRA 31-112985、DEKRA 31-111496、TUV R50436193 0001、TUV R50436194 0001

Product description:

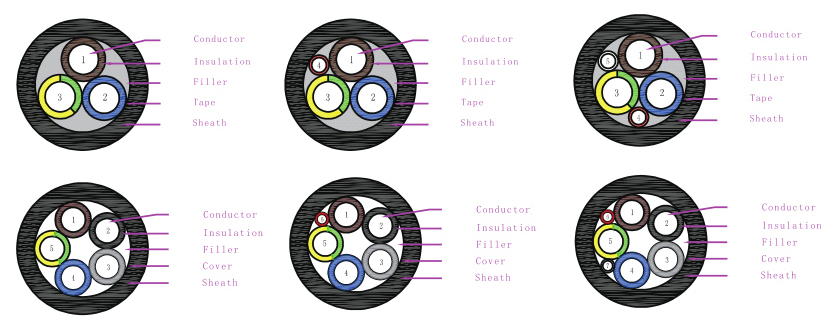

| Construction | Features |

| 1.Conductor | Rated temperature :-40℃~90℃ |

| Material: Bare Copper | Rated Voltage : AC 300/500V、 450/750V;DC 1000V |

| 2.Insulation | Flame Test :Testing method according to EN 60332-1-2 |

| Material: EVI-2 | Min Bending Radius: ≥6*OD |

| Color: Brown,Blue,Yellow/Green | Dielectric Voltage:2.5 kV AC for main core ,2.0 kV AC for CC/CP |

| 3.Filler | Low temperature impact :-40℃, No cracks |

| Material: PP Cord | Hot Shock:150℃/1h No cracks |

| 4.Tape | Oil Resistance :IRM902, 100℃*168h Tensile Strength Variation <±40%,Elongation Variation<±30% |

| Material:Non-woven fabrics | Crush resistance:Sq≤4, crush force≥4KN ; 4≤Sq≤35, crush force≥11KN; |

| 5.Sheath | Resistance to Acid and alkali:168h, Tensile Strength Variation ≤30%; Elongation≥100% |

| Material: TPU | Environmental Requirements:Compliant with RoHS 2.0 and REACH |

| Color: Any color |

| Product number | specification (The signal line is designed according to the needs of use) | Conductor twisted outer diameter | Conductor resistance | Reference allowable current | Unshielded Complete outer diameter | Cable packaging |

H05BZ-F 62893ICE121 |

3×1.5mm2+(0~6)×(0.5~1.0)mm2 | 1.6 | 13.3 | 10A | 8.6~9.6 | 800m/700# |

| 3×2.5mm2+(0~6)×(0.5~1.0)mm2 | 2.1 | 7.98 | 16A | 9.8~10.8 | 800m/700# | |

H07BZ-F 62893ICE123 |

3×1.5mm2+(0~6)×(0.5~1.0)mm2 | 1.6 | 13.3 | 10A | 8.8~9.6 | 800m/700# |

| 3×2.5mm2+(0~6)×(0.5~1.0)mm2 | 2.1 | 7.98 | 16A | 10~10.8 | 800m/700# | |

| 3×4.0mm2+(0~6)×(0.5~1.0)mm2 | 2.8 | 4.95 | 20A | 11.5 | 500m/700# | |

| 3×6.0mm2+(0~6)×(0.5~1.0)mm2 | 3.5 | 3.30 | 32A | 13.2 | 400m/800# | |

| 3×10.0mm2+(0~6)×(0.5~1.0)mm2 | 4.5 | 1.91 | 40A | 16.3 | 500m/950# | |

| 3×16mm2+(0~6)×(0.5~1.0)mm2 | 5.7 | 1.21 | 63A | 19 | 500m/700# | |

| 5×2.5mm2+(0~6)×(0.5~1.0)mm2 | 2.1 | 7.98 | 16A | 13.5 | 500m/950# | |

| 5×4.0mm2+(0~6)×(0.5~1.0)mm2 | 2.8 | 4.95 | 20A | 15 | 400m/950# | |

| 5×6.0mm2+(0~6)×(0.5~1.0)mm2 | 3.5 | 3.30 | 32A | 16.8 | 300m/950# | |

| 5×10.0mm2+(0~6)×(0.5~1.0)mm2 | 4.5 | 1.91 | 40A | 20 | 300m/1200# | |

| 5×16mm2+(0~6)×(0.5~1.0)mm2 | 5.7 | 1.21 | 63A | 23.5 | 800m/700# | |

| 5×25mm2+(0~6)×(0.5~1.0)mm2 | 7.2 | 0.78 | 80A | 29 | 800m/700# | |

| 5×35mm2+(0~6)×(0.5~1.0)mm2 | 8.4 | 0.554 | 125A | 32.8 | 500m/700# |

The above product specifications, sizes, and structures may be changed due to technological progress. Similar specifications can be designed and manufactured according to customer needs.

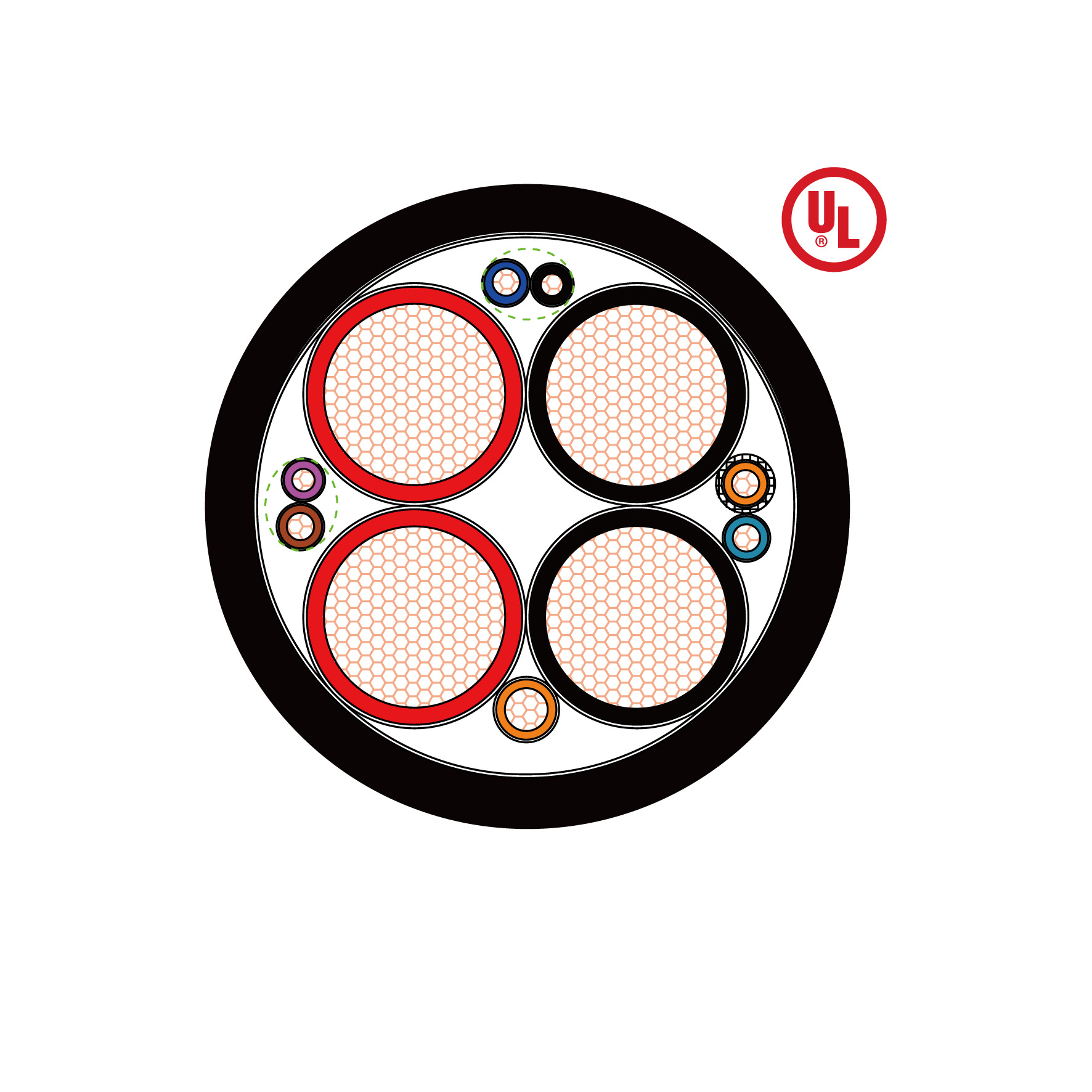

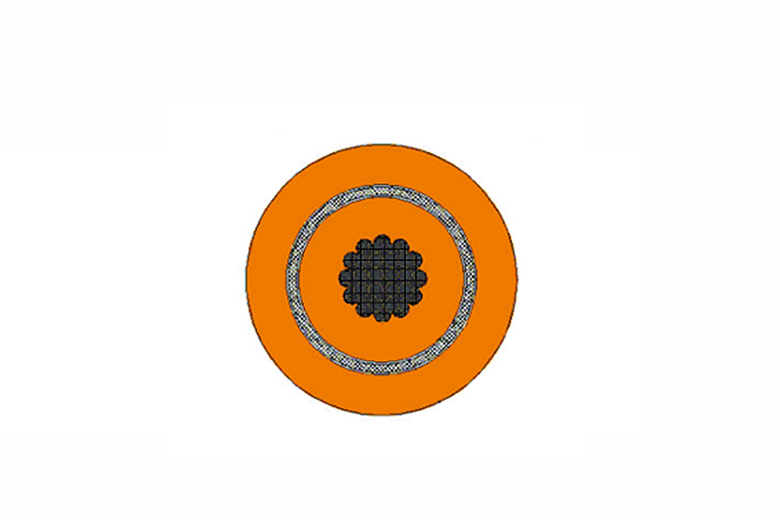

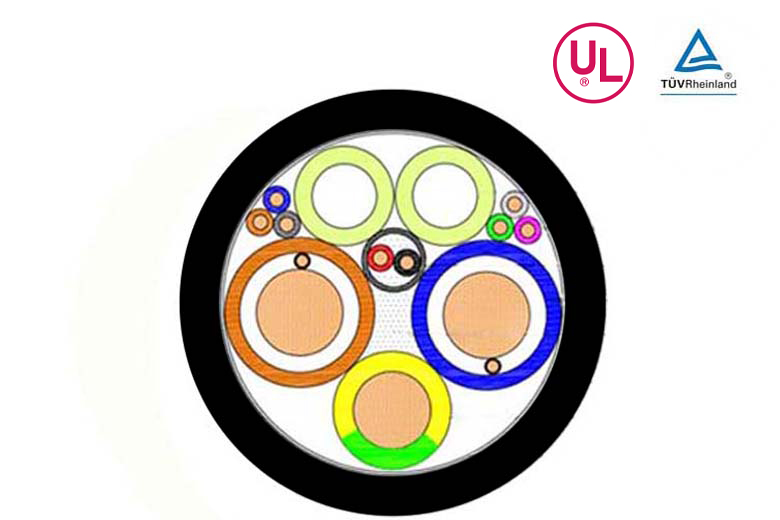

IEC62893 standard DC charging cable product introduction:

TUV certified DC charging cable

Reference Standard :IEC62893-4-1:2020

Certificate number R 50438281 0001

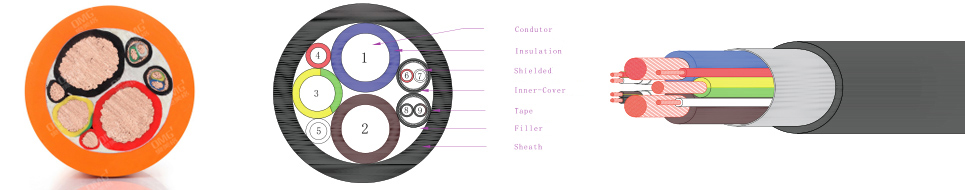

Product description

| Construction | Features |

| 1.Conductor | Rated temperature :-40℃~90℃ |

| Material: Bare Copper | Rated Voltage: DC1500V |

| 2.Insulation | Flame Test:Testing method according to EN60332-1-2 |

| Material:EVI-2 | Bending Radius:≥6*OD |

| Color: Yellow/Green,Blue,Brown、Black、Gray | Dielectric Voltage:2.5kVAC for main core,2.0kV AC for CC/CP |

| 3.Filler | Low temperature impact:-40℃No cracks |

| Material:PP or cotton yarn | Hot Shock:150℃/1h No cracks |

| 4.Tape | Oil Resistance:IRM 902 100℃168h Tensile Strength Variation<±40%, |

| Material:Non-woven fabric | Elongation Variation<±30% |

| 5.Sheath | Crush resistance:Sq≤4crush force ≥4KN;4≤Sq≤35 crush force≥11KN |

| Material:TPU | Resistance to Acid and alkali:168hTensile Strength Variation≤30% Elongation ≥100% Environmental Requirements:Compliant |

| Color: Any color | with RoHS2.0 and REACH |

| Product number | Specification | Conductor twisted outer diameter |

Conductor resistance |

Reference allowable current |

Unshielded Complete outer diameter |

cable packaging |

| 62893 IEC 126 | 2×10+10+P(2×0.75)+4×0.5 | 4.5 | 1.91 | 40A | 15.5 | 300m/950# |

| 2×16+16+P(2×0.75)+4×0.5 | 5.7 | 1.21 | 63A | 18 | 300m/950# | |

| 2×25+16+P(2×0.75)+4×0.5 | 7.1 | 0.78 | 100A | 24.5 | 300m/950# | |

| 2×35+16+P(2×0.75)+4×0.5 | 8.4 | 0.554 | 125A | 25.8 | 300m/950# | |

| 2×50+25+P(2×0.75)+4×0.5 | 10.2 | 0.386 | 150A/200A | 30.2 | 400m/1200# | |

| 2×70+35+P(2×0.75)+4×0.5 | 12.0 | 0.272 | 200A/250A | 34.7 | 400m/1200# | |

| 4×50+50+6×0.75 | 10.0 | 0.386 | 300A/350A | 38.5 | 300m/1200# | |

| 4×60+70+6×0.75 | 11.0 | 0.319 | 350A/400A | 43.5 | 200m/1200# | |

Specifications: 2-core power cable 4mm² to 95mm² or 4-core power cable 50mm² to 260mm², 1-core PE cable 4mm to 70mm, 2-core auxiliary power cable 2.5 mm to 6.0mm (optional) 0-12 core signal cable 0.5mm to 1.0mm can be added, the signal cable can be shielded or the main cable can be shielded. Specific product parameters shall be subject to the technical drawings.

|

||||||

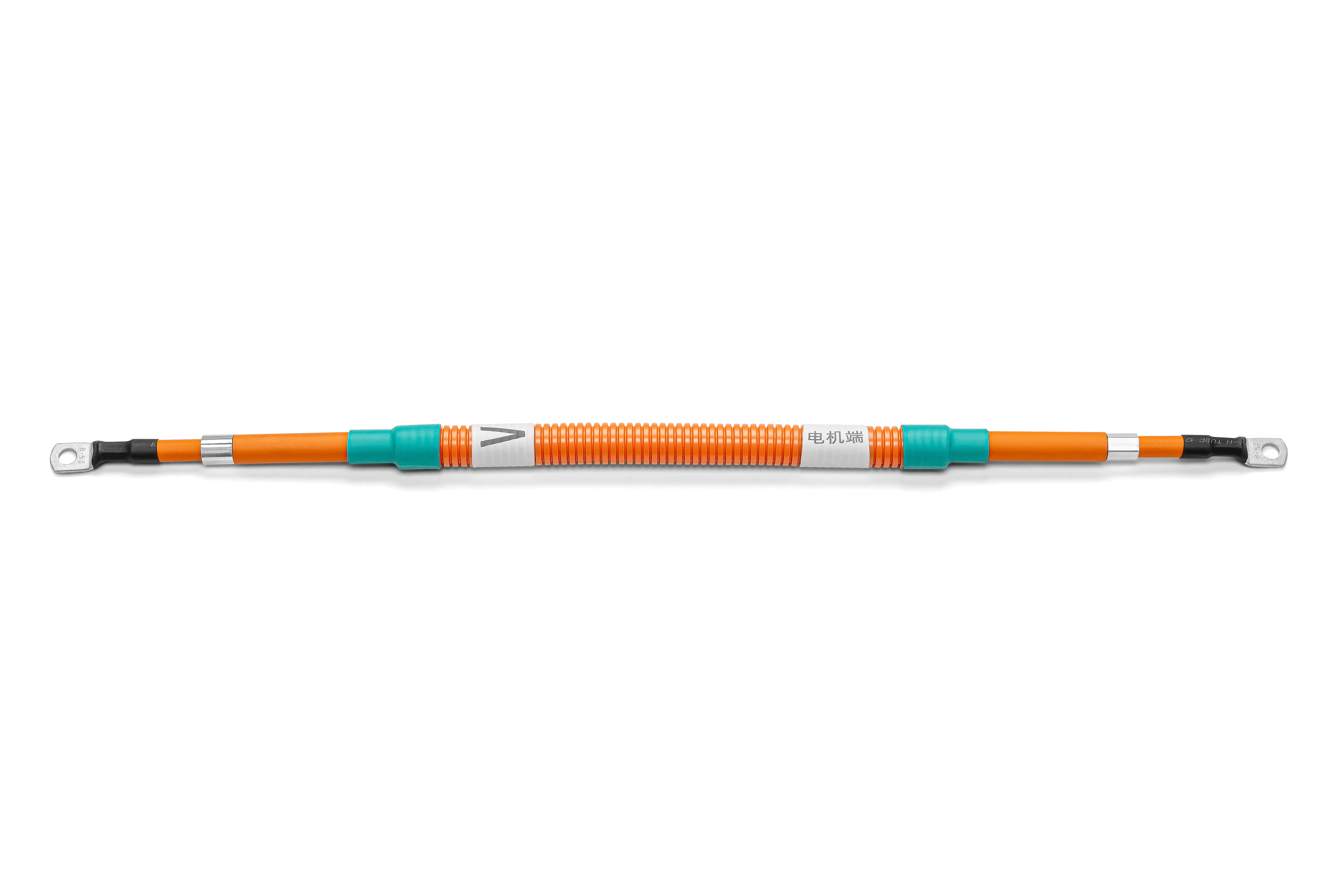

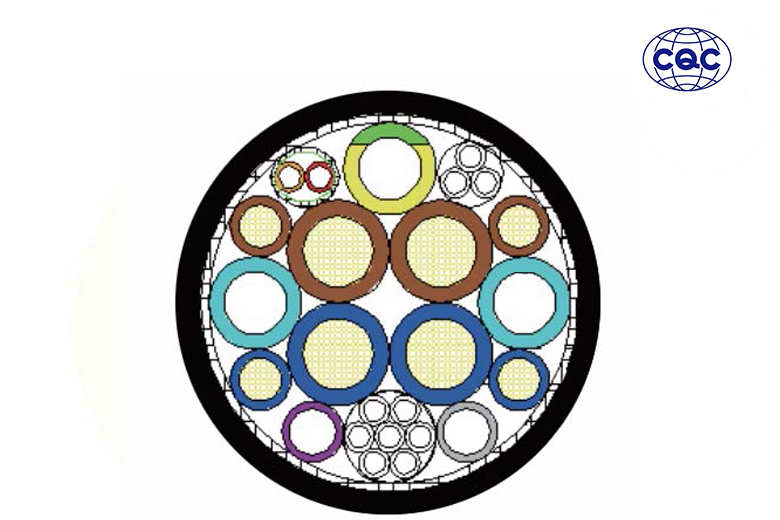

TUV certified AC spring charging cable

Reference standard: EN50620、IEC62893

Certificate No.: R 50436193 0002

| Spring cable | Size | Conductor Stranded OD Ref. mm | Max. Conductor resistance mΩ/m@20℃ | Permissible ampacity@20℃ ambient Ref. | Non-shielded Over diameter mm Ref. | Packing M/Reel(Ref.) |

| EVC H05BZ5H8-F Extensible 62893 IEC 121 | 3×1.5mm²+(0~6)×(0.5~1.0)mm² | 1.6 | 13.3 | 10A | 10.0 | TBD |

| 3×2.5mm²+(0~6)×(0.5~1.0)mm² | 2.1 | 7.98 | 16A | 11.2 | TBD | |

| EVC H05BZ5H8-F Extensible 62893 IEC 121 | 3×1.5mm²+(0~6)×(0.5~1.0)mm² | 1.6 | 13.3 | 10A | 10.0 | TBD |

| 3×2.5mm²+(0~6)×(0.5~1.0)mm² | 2.1 | 7.98 | 16A | 11.2 | TBD | |

| 3×4mm²+(0~6)×(0.5~1.0)mm² | 2.8 | 4.95 | 20A | 12.5 | TBD | |

| 3×6mm²+(0~6)×(0.5~1.0)mm² | 3.2 | 3.3 | 32A | 13.3 | TBD | |

| 5×2.5mm²+(0~6)×(0.5~1.0)mm² | 2.1 | 7.98 | 16A | 13.3 | TBD | |

| 5×4mm²+(0~6)×(0.5~1.0)mm² | 2.8 | 4.95 | 20A | 15.5 | TBD | |

| 5×6mm²+(0~6)×(0.5~1.0)mm² | 3.2 | 3.3 | 32A | 16.5 | TBD | |

| The specific parameters of product should be according to technical drawings. | ||||||