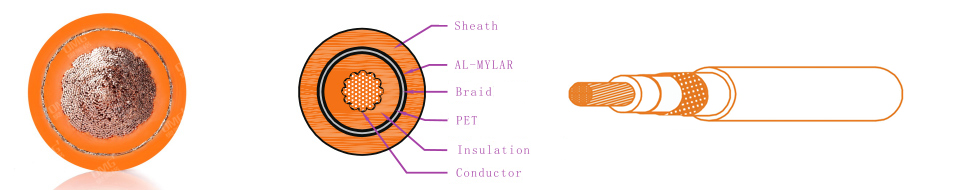

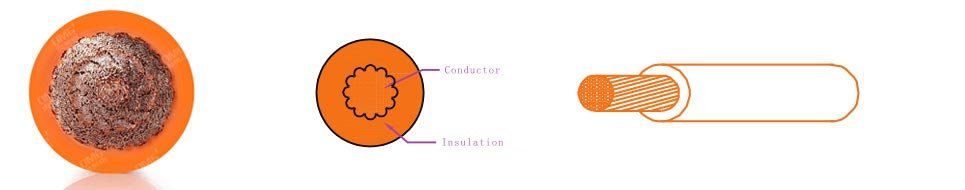

Electric vehicle high voltage cable is an important carrier for power transmission, providing high voltage and strong electricity for the vehicle, and playing the role of performance guarantee and safety guarantee in the whole vehicle. It consists of conductor, insulation, wrapping tape, braiding, aluminum foil and sheath from inside to outside. It is generally used to connect the charging port to the battery, inside the battery, the battery to the engine and other components, as well as battery energy storage equipment and other fields.

Due to the harsh application environment in the car, the high voltage cable for electric vehicles has very high performance requirements. Electric vehicles with cable application occasions characterized by: wiring space is small, high current and high voltage, high and low temperature environment, more heat dissipation is not good, the car driving environment is harsh salt spray and electromagnetic fields, oil and chemicals, low smoke halogen-free flame retardant and other environmental protection and safety requirements. Therefore, the electric car high-voltage cable must be strictly in accordance with the standards for production, testing, to ensure that the cable corrosion resistance, high and low temperature resistance, wear resistance and other characteristics, so as to ensure that the car can be a long time stable operation.

At the same time, the insulation material chosen is also important to ensure the safety of high voltage cables. High-voltage cable shielding materials are LSZH, TPE, XLPE and silicone rubber. Commonly used XLPE is crosslinked polyethylene, by the temperature resistance level of 75 ℃ polyethylene material after the change into the temperature resistance level can be as high as 150 ° C. Light weight, high heat resistance, corrosion resistance, insulation resistance and other characteristics of the larger, and the service life is relatively long.

OMG' is committed to become the world's first-class new energy charging application technology provider, and in 2017 was named as one of the top 100 enterprises of core components for electric vehicles, through the ISO 9001:2015 and IATF 16949:2016 system certification.OMG's in-vehicle high-voltage cable products are implemented in IS0 19642-2019-5, IS0 19642-2019- 9, LV216-2, UL758 and other international standards, and also widely produces domestic standard products mainly based on QC/T 1037. On this basis, we have also introduced enterprise standards higher than the industry standards and upgraded to local standards in Guangdong Province, with the standard number DB44/T 2100-2018.According to different scenarios, we provide customers with specification references, such as drive motors - MCU commonly used specifications are 35mm², 50mm², 70mm²*3; air conditioning system - PDU commonly used specifications for 2.5mm², 4mm², 6mm²*2; vehicle charger commonly used specifications for 6mm², 10mm², etc. Commonly used materials are 180°C silicone and 125, 150, 200°C cross-linked polyethylene. Conductor materials include bare copper, tinned copper and aluminum alloy. In addition, we can also customize the products according to customer needs. For more information, please contact: Leo@omgevcable.com

Related Recommendations:

Test OMG EV high voltage cable (Part 1)

Test OMG EV high voltage cable (Part 2)