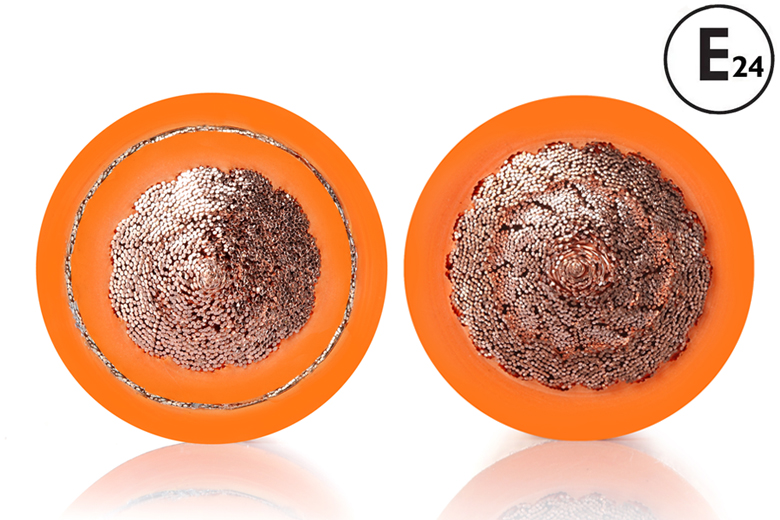

With the rapid development and popularization of electric vehicles, copper core high voltage cables, as an important part of the electric vehicle charging system, have many advantages.

1. Excellent electrical conductivity: copper is an excellent conductive material with low resistivity and high electrical conductivity. Copper-core high-voltage cable than aluminum core resistivity is about 1.68 times lower, so the same cross-section of copper-core high-voltage cable than aluminum-core high-voltage cable allows a higher current-carrying capacity of about 30%, which can effectively transmit high-voltage electrical energy, reduce energy loss and improve charging efficiency. At the same time, due to the low resistivity of the copper core, in the same cross-section flowing through the same current, copper-core high-voltage cable conductivity is better; transmission distance is the same, to ensure better voltage quality. Under the condition of permissible voltage drop, copper-core high-voltage cable transmission can reach a longer distance, that is, the power supply covers a large area, which is conducive to the planning of circuit wiring.

2. Good thermal conductivity: Electric vehicle charging process will generate a certain amount of heat, copper core high voltage cable has good thermal conductivity. Under the same current, the heat generation of copper core cable with the same cross-section is much smaller than that of aluminum core cable, which can quickly conduct the heat to the external environment, prevent the cable from overheating and ensure the safety of the charging process.

3. High strength and durability: Copper-core high-voltage cables are made of high-quality copper materials, the flexibility of the cable is also about 1.8 times higher than that of aluminum, and it is not easy to break after repeated use of pressure and folding. Allowable stress at room temperature, copper than aluminum were 7 to 28% higher. Especially at high temperatures under stress, copper is a high strength and durability, able to withstand high pressure and frequent use, to extend the service life of the cable.

4. Antioxidant and corrosion resistance: the surface of copper-core high-voltage cables are usually treated with special antioxidant and corrosion-resistant treatments, and the connectors have stable performance, which can effectively prevent the occurrence of oxidation and corrosion, and keep the performance of the cable stable.

5. Flexibility and plasticity: copper-core high-voltage cables have good flexibility and plasticity, the ductility of copper alloy is 20~40%, the ductility of copper for electrical use is more than 30%, good flexibility, to adapt to different installation environments and wiring needs, convenient installation and maintenance.

6. Strong anti-interference ability: copper-core high-voltage cable using shielding technology, can effectively reduce the external electromagnetic interference on the cable, improve the cable's anti-interference ability and signal transmission quality.

In short, electric vehicle copper core high voltage cable has excellent electrical conductivity, thermal conductivity, strength and durability, as well as oxidation resistance, corrosion resistance, flexibility and strong anti-interference ability. These advantages ensure the safety, reliability and efficiency of the electric vehicle charging system and promote the development of the electric vehicle industry. With the continuous progress of technology, copper core high voltage cables will continue to play an important role in the field of electric vehicles.

OMG' has been committed to providing professional electric vehicle electric energy conduction solutions for global customers for many years, and has passed the ISO 9001:2015 and IATF 16949:2016 system certification.OMG' in-vehicle high-voltage cable products implement ISO6722-1, ISO6722-2, ISO14572, LV216, ISO19642, UL758 (UL3820\UL30088) and other international standards and QC/T1037-based Chinese standards. The cables can be customized according to the specific needs of customers, and the conductor materials are available in various conductor types such as bare copper, tinned copper and aluminum alloy. Contact OMG's engineers for more information on cable selection:Leo@omgevcable.com